Quadrant has various custom designed testing machines for magnetic measurements. Below are two magnetic mapping systems outlined with descriptions as a combination of our engineering solutions.

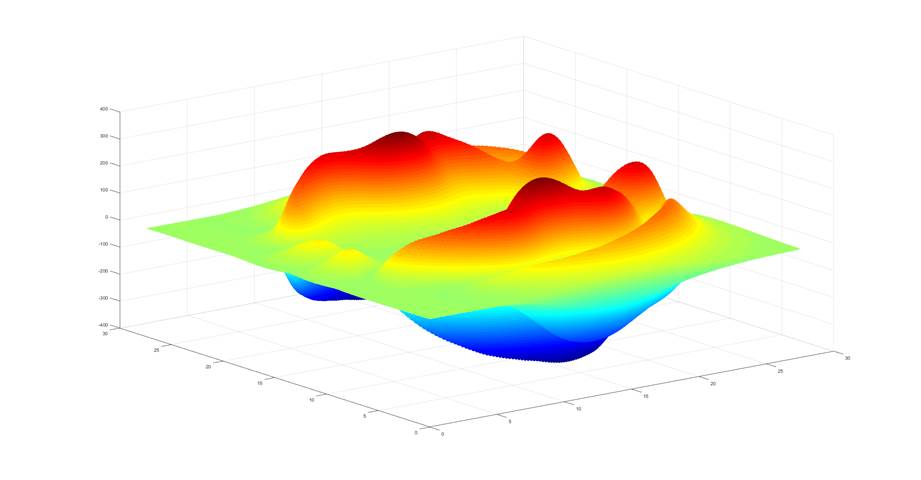

Magnetic field mappers measures the field magnitude and direction over a predetermined range of positions. These measurements are made by accurately positioning a collection of three or more Hall Effect sensors and recording their output. A large bank of very many data points allows the evalsuation of curls and trends with greater reliability. The resulting data can be manipulated for many purposes; from determining if a computer will demagnetize a hotel room key to determining if a phones mount will reprogram a heart pacemaker.

When field mappers first became commercially available, Quadrant purchased the Brockhaus 460 Scanner to measure magnetic field amplitude, polarity, and the direction in a 400 mm cube in 0,1 mm steps.

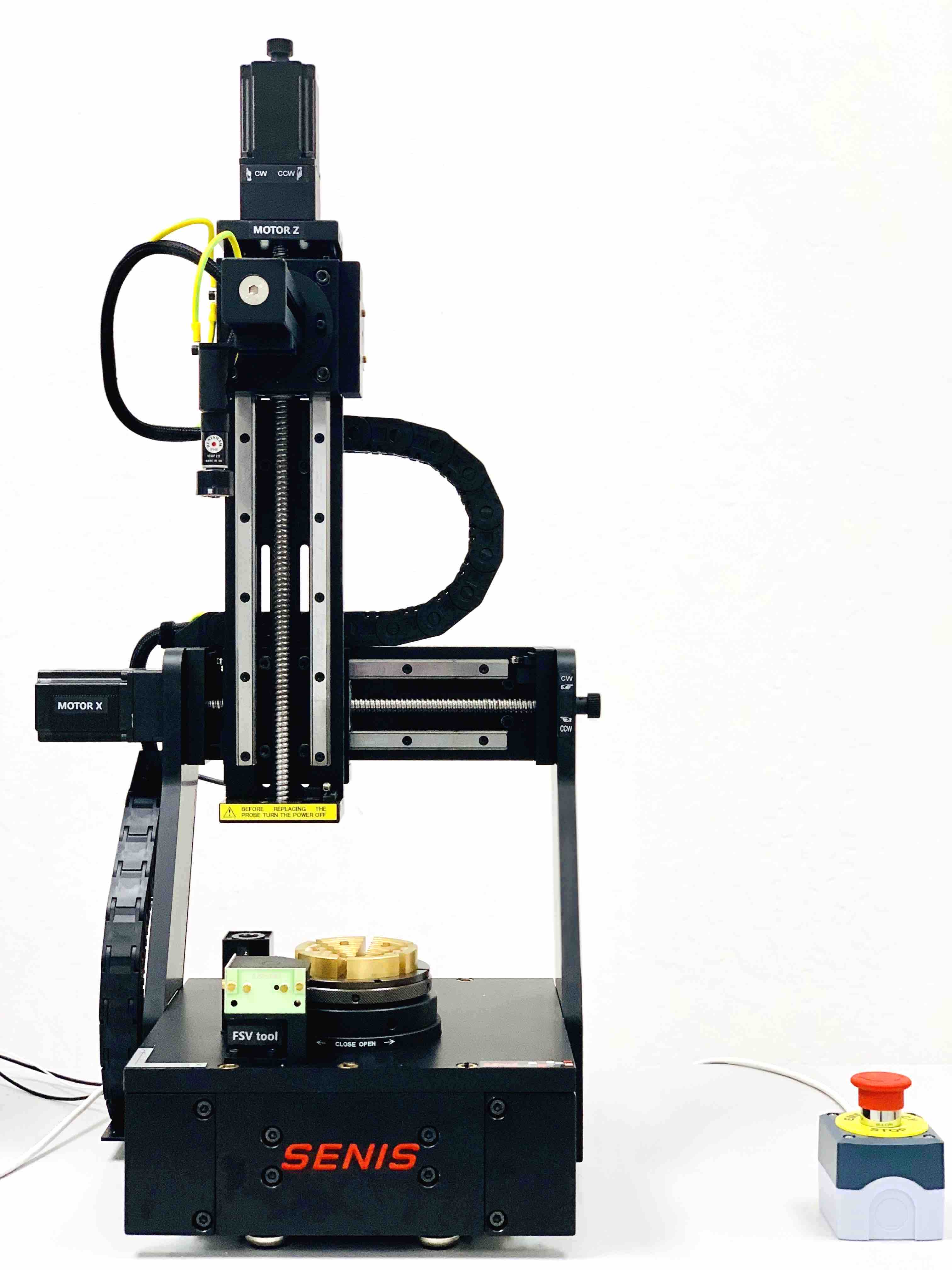

Our newest field mapper is a Senis model MMS-1A-RS. It measures flux density inside a 135 mm cube, in 2 µm steps, with 0.1% accuracy. It can measure in standard X, Y, Z coordinates, or the magnet assembly can be placed on a rotating base to enable r, θ, Z positional coordinates for motor and rotational sensor data. Subprograms enable key data to be output in various ways.

Quadrant engineers utilize field mapping data in many ways. We often evalsuate a customer’s current product and use that data as a starting point for product improvement. We sometimes measure a product and compare to calculated values so that we can tune our evalsuation methods for better design accuracy. And we sometimes use it, on complex assemblies, as a final inspection tool to evalsuate the finished product. Field mapper data provides a wealth of information that cannot be obtained by any other equipment.

The magnetic field technique required may vary based on your need or application. If your application requires a dedicated analysis and has not been outlined above, please ask our engineering team for advice.